MFM 310

The Rigaku MFM310 performs high-precision measurements not possible by optical or ultrasonic techniques. This sophisticated X-ray metrology tool makes it practical to perform high-throughput measurements on product and blanket wafers ranging from ultrathin single-layer films to multilayer stacks.

Designed for high-volume manufacturing

The MFM310 is designed with high-volume 200mm and 300mm manufacturing in mind: high-throughput thickness measurement by XRR and XRF, low-contamination wafer handling and pattern recognition-based position control for product wafer measurements, CE Marking and S2/S8 Compliance for semiconductor production clean room operation, compliance with GEM-300/HSMS and factory automation standards, high-reliability machine performance and low power consumption and cost of ownership.

COLORS™ enabling technology

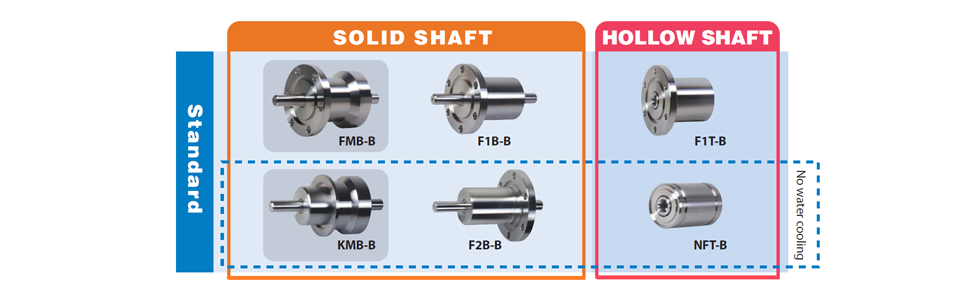

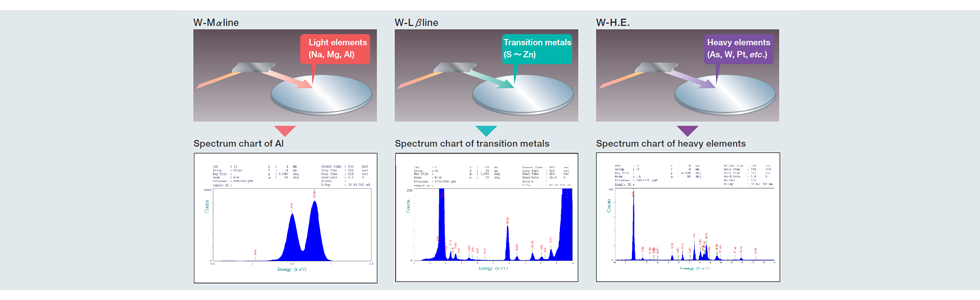

COLORS™ X-ray optics were developed by Rigaku for the MFM310 to enable measurements from small areas. COLORS beam modules couple a variety of XRF excitation sources with optics and are optimized to provide high brightness in small spots for a variety of thin film applications. With its own x-ray optics business, Rigaku is well-positioned develop and manufacture X-ray sources for current and future market needs.

Features

- Micro-spot X-ray beams and pattern recognition

- High-throughput, product-wafer measurements

- Wide range of materials and applications

- High resolution and precision covering thicknesses from Ångstroms to microns

- For 200mm and 300mm wafers

- Available with 300mm factory automation

- Design based on SEMI S2 and SEMI S8