TXRF 310e

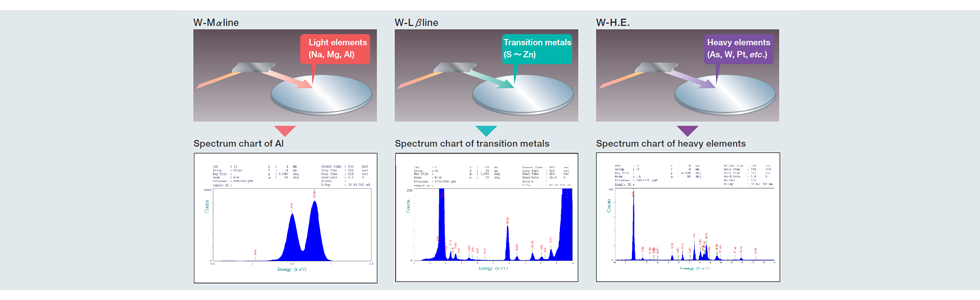

TXRF analysis can gauge contamination in all fab processes, including cleaning, litho, etch, ashing, films, etc. The TXRF-310e can measure elements from S through U with a single-target, dual-beam X-ray system and a new liquid nitrogen-free detector system.

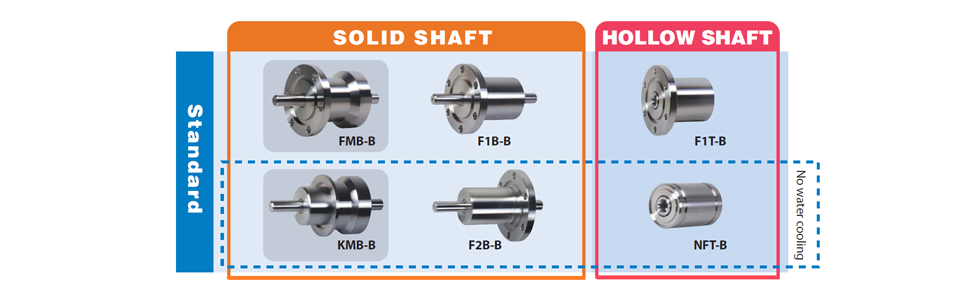

The TXRF-310e includes Rigaku's patent pending X-Y-θ sample stage system, an in-vacuum wafer robotic transfer system, and new user-friendly windows software. All of these contribute to higher throughput, higher accuracy and precision, and easy routine operation.

Optional Sweeping TXRF software enables mapping of the contaminant distribution over the wafer surface to identify "hot spots" — out to zero edge exclusion.

Features

- Ease of operation and rapid analysis results

- Accepts 300 mm, 200 mm, and 150 mm wafers

- Low cost of ownership

- Sealed X-ray tube source

- Wide range of analytical elements (S~U)

- Application to bare Si and to non-Si substrates

- Zero edge exclusion (ZEE-TXRF) measurement capability

- Import measurement coordinates from defect inspection tools for follow-up analysis

- FOUP, SMIF, and through-the-wall configurations are available to meet the various needs of high-volume manufacturing wafer fabs